Customized packing design

We manufacture a wide variety of coextruded polyethylene bags. The top opening allows them to be either sewn or heat-sealed when filled on manual or automatic production lines.

Available in different styles, depending on the product to be stored:

Tubular open-mouth bags (with or without gussets)

Open-mouth bags with side seal (with or without gussets)

Open-mouth bags with side seals (with or without gussets)

Features

Ideal for:

Mostly used in gravity filling machines and high-speed filling lines.

VALVE BAGS (R-TYPE)

Ideal for:

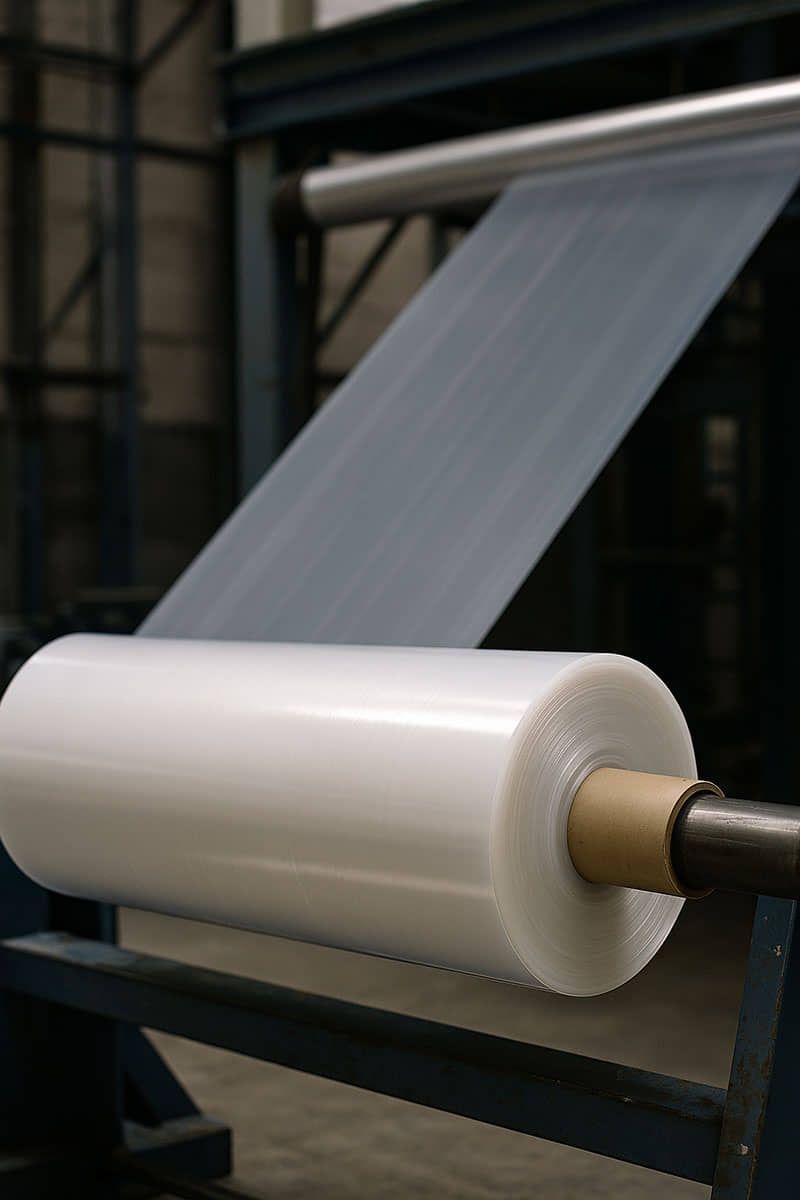

FFS FILM (FORM, FILL & SEAL)

Using "Form, Fill & Seal" technology, these films provide a durable, coextruded packaging solution that ensures excellent seal strength and high filling speed. They are ideal for packaging dry solids and raw materials.

Features:

SHRINK FILM

Shrink film and packaging made from 100% virgin resin, custom-designed to provide the best packaging solution with high shrinkage, excellent strength, and outstanding optical and mechanical properties.

Packaging and palletizing various products in the:

INDUSTRIAL FILMS

Industrial film is a flexible and durable material widely used in various industries for product protection and packaging. Its versatility makes it the ideal option to ensure the safety of goods during transport, storage, and handling.

Flat film (with or without gussets)

Open-side tubular film

Perforated roll film

Waterproofing film

Ideal for wrapping and protecting products of various shapes and sizes in:

LOW MELT OR BATCH INCLUSION FILMS

Low-melting-point films and bags melt at lower temperatures than standard materials.

Types

Films

Bags

Open-mouth and valve bags

Characteristics:

Ideal for:

LOW-DENSITY POLYETHYLENE BAGS

Our low-density polyethylene bags are made with FDA-approved resins and additives. They stand out for their flexibility, high resistance to impact, darting, and elongation. Additionally, their ability to resist chemicals, along with their low cost and ease of recycling, makes them an excellent option to meet current market demands.

They can be presented as loose bags or perforated rolls. All sizes can be printed and pigmented in the color of your choice.

Perforated roll bags

Ice bags

Frozen product bags

Biodegradable bags

Trash bags

Resin bags (FFS Bags LDPE pellets)

Micro-perforated bags and rolls

VCI bags

Features:

Thanks to their versatility, they are widely used for packaging products such as

HIGH-DENSITY POLYETHYLENE BAGS

Our high-density polyethylene bags offer good heat-sealing response and resistance to tear propagation.

Loose bag with bottom seal

Loose bag with side seal

Loose bag with star seal

Roll bag with spool and bottom seal

Roll bag with spool and side seal